Sign consistency and quality control begins with the standard of each customer product line. Shop drawings and CAD drawings are set for every department, enabling us to perform several different fabrication functions simultaneously. When its time for final assembly all the components of the signage are ready.

Prosel uses a lean manufacturing process in our assembly lines where products are fabricated at specific a located departments. When a signage component moves from one department to another it is inspected and the work order is reviewed.

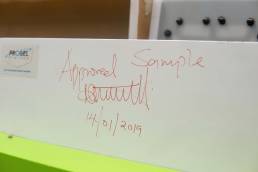

Quality control measures including visual controls, templates and guides are place at various departments to ensure operators avoid mistakes. Upon completion, the sign is thoroughly inspected for workmanship, safety and whether it meets the clients brand standards. Lastly, the product is inspected for proper labeling and designation before being loaded for delivery.

Lean manufacturing assembly line enables us to closely inspect the quality of every single sign we manufacture, not just every three or five sign.

As well as providing individual attention we also increase efficiency and product flow.